The concept is simple and elegant: balance the weight of the gasket, with an item of similar weight placed on the exact opposite side.

Fulcrum® has a long-standing reputation for the extremely high performance of its hubs in terms of smoothness and reliability.

In fact, all the projects are entirely developed in our R&D department and we have put obsessive care into taking care of every detail.

The hubs with USB™ ceramic bearings (Ultra Smooth Bearings) further enhance the triathlon and road bike wheels’ smoothness and reduce weight and the need for maintenance.

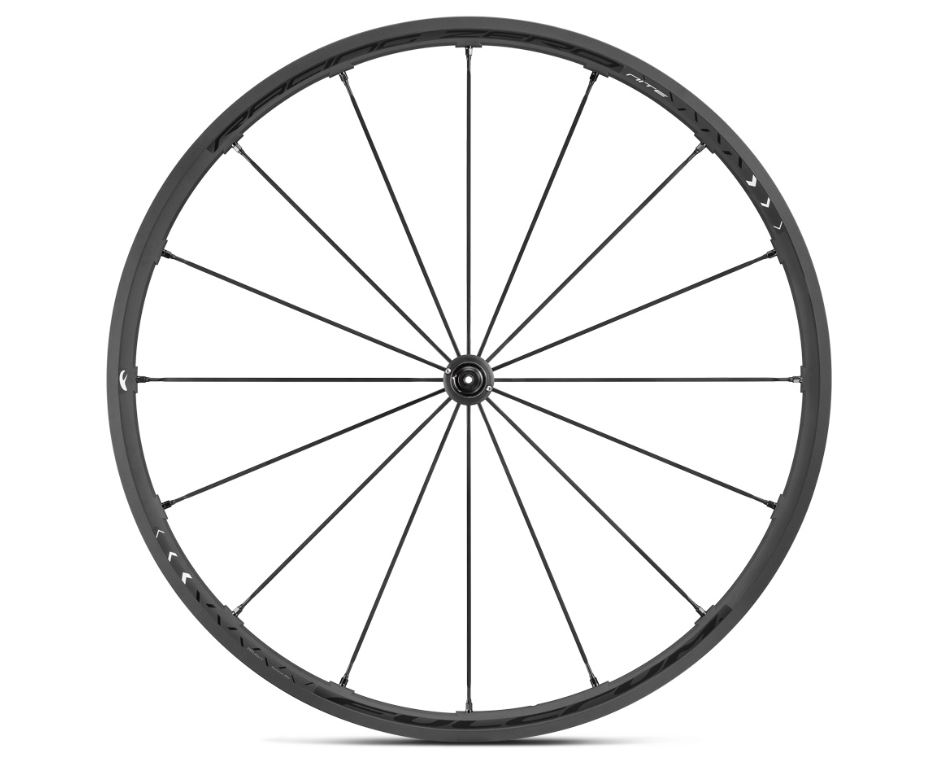

DRSC™ – DIRECTIONAL RIM-SPOKE COUPLING

Exclusive rim/spoke coupling system. It allows the rim, spokes, nipples, and hub to align properly with the same tensioning value in all areas.

MOMAG™

What is MoMag™?

A magnet and lots of ingenuity. This was what led to the patent for the well-tested “Mounting Magnet” system, or MoMag™.

ANTI-ROTATION SYSTEM™

This new system raises the concept of spoking to a new level of performance for a road bike and triathlon wheels ( and mtb too)

The Fulcrum® engineers have redesigned the spokes and the hub housings to create a solid and unmoveable whole. The result is that the spokes

a) will never lose their initial tension, thus keeping the wheel perfectly reactive and centered

b) will remain in the position that has been studied in the wind tunnel tests to ensure the best aerodynamic penetration possible.

TRACEABILITY

A guarantee of quality

The keyword for our products is traceable.

If you find a little label attached to any Fulcrum® product, do not remove it. It will provide you a guarantee in case of an ascertained defectiveness of a production batch, and so the component needed or wheel will be traceable.

All this because, devoted to its mission, Fulcrum® demands the absolute perfection and safety for its customers.

PLASMA ELECTROLYTIC OXIDATION

The Plasma Electrolytic Oxidation treatment is a process made through electrical discharges that take advantage of heavy materials and free electrolytes.

This process is an advanced oxidation process of light alloys of aluminum, magnesium, and titanium. This special project was developed a few decades ago in the Russian laboratories to improve characteristics of the lightweight materials used in the space and military spaces

The Plasma Electrolytic Oxidation process gives the alloy surface very special characteristics regarding hardness and wears resistance.

THE CHEMICAL PROCESS

This is possible thanks to a very fine and compact matrix of alpha and microcrystalline gamma alumina and amorphous alumina embedded on the surface.

Road bike wheels treated with Plasma Electrolytic Oxidations take a new really engaging total black look, also interesting for the excellent wear resistance thanks to the high hardness of the layer.

Fulcrum® R&D department has chosen to use this treatment also on the aluminum braking surface, developing a new design created by turning that allows superior braking efficiency.

Specified brake pads should be used with this special finishing.

WIDE RIM TECH

Fulcrum®’s R&D department, following requests from the competition circuit, has worked to create rims that are wider than before, about 4 mm or more than previously. This technical choice provides an ideal basis for 25/28mm tyres, the sizes currently popular.

This ensures stability, excellent handling, and superior comfort.

THE ADJUSTING RING

The adjusting ring lets you pre-load the bearing, so you can eliminate side-to-side play and have optimum adjustment once the wheel is mounted on the frame.

CUP & CONE

The cup-and-cone bearing differs from the classic cartridge bearing because it works in perfect alignment with the forces involved, weight and thrust from the frame, as the bearings run in a race positioned directly opposing these forces.

SQUARE MILLING

For the new Racing Zero’s aluminum rim, we decided to keep the triple-milled structure throughout the profile to minimise aluminum thicknesses. Next, our technicians added 3D milling at the base of the spokes.

This means less material but the same reliability since, in this particular design, the forces are well distributed over the rim.

Triple and “Square” milling enable maximum weight reduction on the rim periphery, producing an extremely responsive wheel.

DIFFERENTIATED RIM HEIGHT

Two different heights for front and back. A bigger challenge in construction, but necessary to achieve the very best.

The lower front wheel improves handling, limiting weight to a maximum and also mass involved when turning and relaunching.

The rear rim is higher and more solid, to transmit all the power to the wheel and increase stability.

HIGH STRENGTH ALUMINUM

Special aluminum – the best aluminum wheels require carefully chosen materials. For “High strength Aluminum”, Fulcrum® R&D uses only the best aluminum alloy 6082, with artificial aging T6 temper that stabilizes the alloy and gives it maximum life and reliability.

Aluminum 6082 has the highest strength of the 6000 series and has replaced 6061 in many applications. It is generally used for high-stress applications.

PLASMA FREEHUB

The Plasma treatment makes the aluminum especially hard and resistant to surface abrasion and wear. This has allowed the thickness of materials to be reduced to a minimum, achieving advantages of lighter weight, while maintaining lifespan and reliability.

OVERSIZE FLANGE

The Oversize Flange was developed from the need to create a system to transmit every watt to the ground without dispersion, stiffening the wheel system where necessary, without having to add spokes or superstructures that increase weight.

The oversize flange uses physics to solve the problem. It increases dishing and enables spokes to be shortened. Doubling the spokes creates a balanced system that is excellent at transmitting torque.

Or as low as R6,249 / month interest-free, using your existing credit card. For orders over R2,000.How it works

Or as low as R6,249 / month interest-free, using your existing credit card. For orders over R2,000.How it works